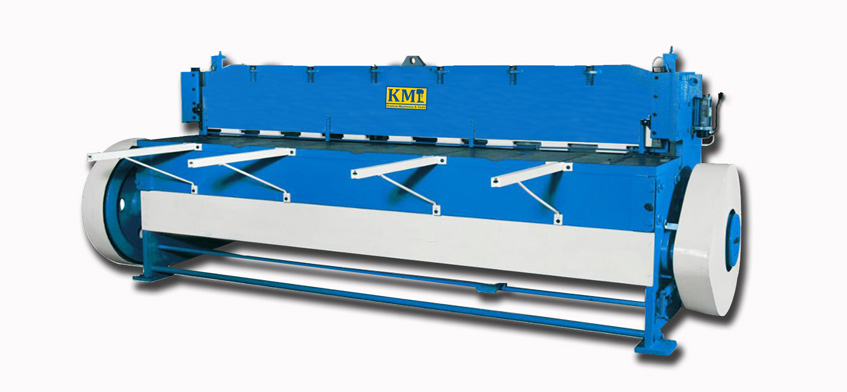

Mechanical Shearing Machine

Under crank Mechanical Motorized Shearing Machine

KMT' Shearing Machines have been designed and developed through structural analysis technique for continuous production, accuracy and repeatability. Shearing are available in Capacities (size) of 4 feet / 5 / 6 / 8 / 10 / 12 feet & 13 feet length thickness of machine is 0.100 mm up to 4 mm capacities, rolling key clutch, spring loaded mechanical hold down pads, increased productivity & reliability having the following main features:

FRAME :

Rigid steel frame of shears are optimally designed to avoid week sections at load support and is of interlocked design. The ram is guided throughout its length by accurate machined guide ways ensuring proper clearance and clean cut.

HOLD-DOWN SYSTEM :

Spring loaded mechanical Hold down pads hold the sheet securely, to avoid slipping and bowing resulting in clean square cuts. Hold-down units are provided with oversize pads to avoid impressions on sheet metal on request.

HOLD-DOWN SYSTEM :

Hydraulic Hold down pads are accurate calm operated pump. Hydraulic Hold down pads hold the sheet securely, to avoid slipping and bowing resulting in clean square cut. Hold down units are provided with oversize pads to avoid impressions on sheet metal on request at extra cost.

KNIVES :

Shears are provided with high quality single segment (HcHcr) Knives for longer tool elite. Ease in assembling of knife reduces down-time. The knife blades are four edged.

LUBRICATION :

All bearing parts and guide surfaces are lubricated through hand-operated lubrication system.

MECHANICAL BACK GAUGE :

This is standard equipment provided on all shears. Scale on back gauge gives instantaneous reading of distance between shear and back gauge. Thus avoiding errors and maintenance uncounted in electronic equipment.

FINGER GUARD :

Fitted in front of hold-down for operator protection without abstracting viewing.

|

Model |

Length Cutting Thickness MM |

Depth of Throat MM |

Stroke Per Minute |

Table Height MM |

Table Width MM |

Front Gauge MM |

Back Gauge MM |

|

KMT-1-UC |

1270×4 |

62 |

45 |

900 |

430 |

500 |

600 |

|

KMT-2-UC |

1525×4 |

62 |

45 |

900 |

430 |

500 |

600 |

|

KMT-3-UC |

2030×4 |

62 |

45 |

900 |

430 |

500 |

600 |

|

KMT-4-UC |

2540×4 |

62 |

45 |

900 |

430 |

500 |

600 |

|

KMT-5-UC |

1270×3 |

62 |

45 |

900 |

430 |

500 |

600 |

|

KMT-6-UC |

1525×3 |

62 |

45 |

900 |

430 |

500 |

600 |

|

KMT-7-UC |

2030×3 |

62 |

45 |

900 |

430 |

500 |

600 |

|

KMT-8-UC |

1270×2 |

50 |

45 |

775 |

325 |

500 |

600 |

|

KMT-9-UC |

1525×2 |

50 |

45 |

775 |

325 |

500 |

600 |

|

KMT-10-UC |

2030×2 |

50 |

45 |

775 |

325 |

500 |

600 |

Over crank Mechanical Motorized Shearing Machine

|

Model |

Shear Capacity In Mild Steel |

Motor Required |

Strokes per minutes |

Max. Back Adjustment |

|

KMT-OCSB-50 |

1250 x 8mm |

10 H.P |

30 |

24” |

|

KMT -OCSC-50 |

1250 x 10 mm |

10 H.P |

30 |

24” |

|

KMT -OCSA-60 |

1500 x 6mm |

10 H.P |

30 |

24” |

|

KMT -OCSB-60 |

1250 x 8mm |

10 H.P |

30 |

24” |

|

KMT -OCSC-60 |

1500 x 10mm |

10 H.P |

30 |

24” |

|

KMT -OCSA-72 |

1820 x 6mm |

10 H.P |

30 |

24” |

|

KMT -OCSB-72 |

1820 x 8mm |

10 H.P |

30 |

24” |

|

KMT -OCSC-72 |

1820 x 10mm |

10 H.P |

30 |

24” |

|

KMT -OCSA-80 |

2000 x 6mm |

10 H.P |

30 |

24” |

|

KMT -OCSB-80 |

2000 x 8mm |

10 H.P |

30 |

24” |

|

KMT -OCSC-80 |

2000 x 10mm |

10 H.P |

30 |

24” |

|

KMT -OCSA-100 |

2540 x 6mm |

10 H.P |

30 |

24” |

|

KMT -OCSB-100 |

2540 x 8mm |

15 H.P |

30 |

24” |

|

KMT -OCSC-100 |

2540 x 10mm |

20 H.P |

30 |

24” |